90+50 Building Cable High Speed Cable Extrusion Machine

1. Application

A 90+50 Cable Extrusion Line refers to a cable manufacturing system

capable of producing cables with two different layers or sizes of

sheathing. The numbers 90 and 50 typically represent the diameters

or cross-sectional areas of the respective layers of the cable.

Here's an overview of how a 90+50 Cable Extrusion Line may

function:

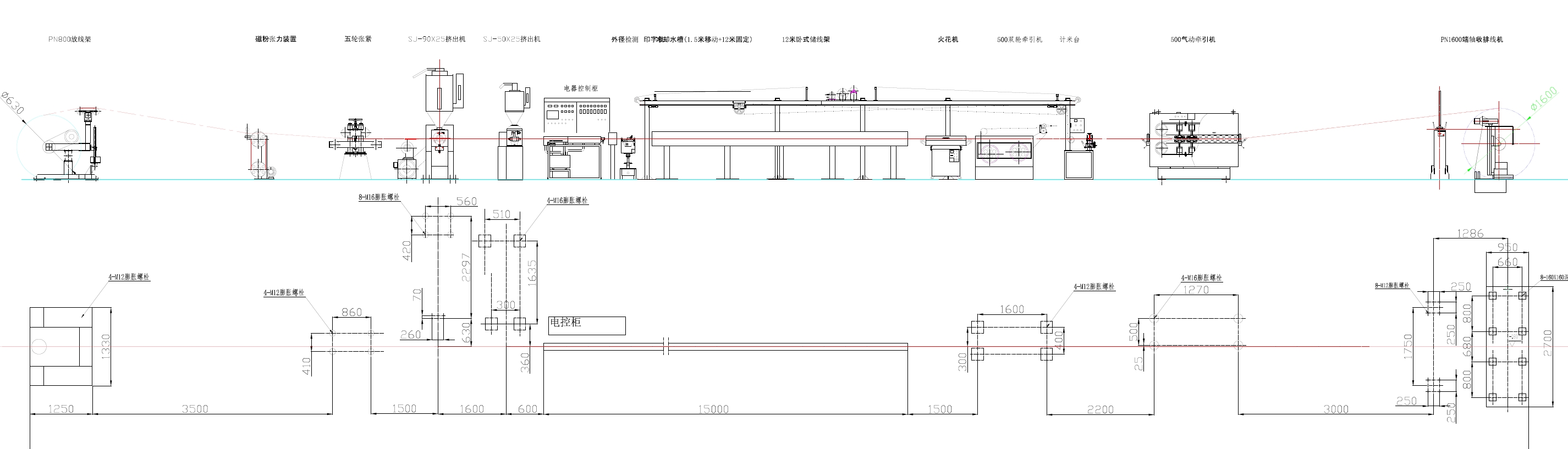

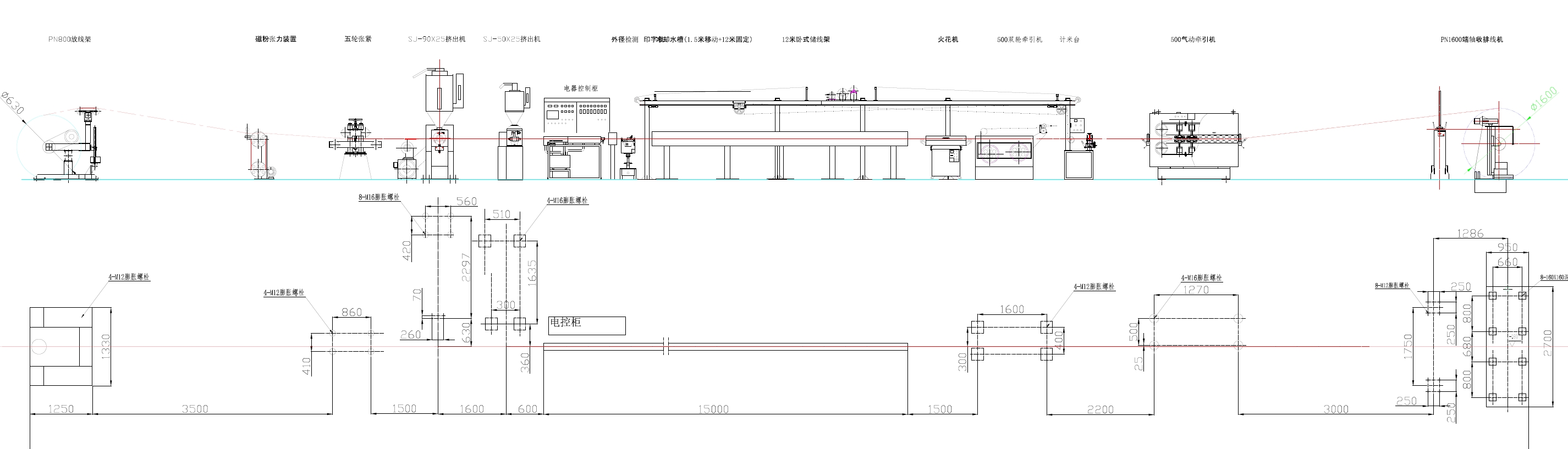

Payoff Unit: The system begins with a payoff unit that unwinds the

conductor wire from a spool or reel and feeds it into the extrusion

line.

Preheating Zone: The conductor wire passes through a preheating

zone to ensure it reaches the appropriate temperature for the

extrusion process.

Extrusion: The cable extrusion line consists of multiple extruders

or co-extruders. In the case of a 90+50 configuration, there are

two extruders for the respective layers of the cable.

Extruder 1: This extruder is designed to extrude the first layer of

sheathing material with a diameter or cross-sectional area of 90.

The plastic material, such as PVC, PE, or PP, is melted and

compressed in the extruder barrel before being forced through a die

to form the desired shape and size of the first layer.

Extruder 2: This extruder is responsible for extruding the second

layer with a diameter or cross-sectional area of 50. The second

layer material is similarly melted, compressed, and forced through

a die.

Cooling System: After extrusion, the cable passes through a cooling

system to solidify the sheathing layers. This can involve water

baths, cooling troughs, or other cooling methods specific to the

cable extrusion line.

Haul-off Unit: A haul-off unit grips the cable and pulls it through

the extrusion line at a controlled speed, ensuring consistent

tension and diameter for both layers.

Marking and Printing: If necessary, the cable may pass through a

marking or printing system to apply identification marks, logos, or

other required information on the sheathing layers.

Accumulator Unit: In case of disruptions downstream, an accumulator

unit temporarily stores the cable while maintaining continuous

extrusion.

Take-up Unit: The finished cable is wound onto a spool or reel

using a take-up unit, which controls tension and speed to

facilitate proper winding.

Throughout the process, sensors and control systems monitor

parameters such as temperature, pressure, and diameter to ensure

quality control and make necessary adjustments.

The specific configuration and features of a 90+50 Cable Extrusion

Line can vary depending on the manufacturer, desired cable

specifications, and customer requirements.

2. Advantages

♦Highly automatic, manpower saving

♦Easy to operate and maintain, start-up friendly

♦Converter applied for adjusting speed, power saving

♦Customization available to meet various customer requirments

Famous Brands Parts:

Motor: Dongguan Motor, Teco, ABB, Siemens

Inverter: Japan Yaskawa, Siemens, Taiwan Teco

Temperature Control Meter: Japan RKC

Auxiliary Relay: Japan Omron

Ammeter and Voltmeter: Taiwan Risesun

Indicator, Switch and Button: Taiwan TEND

Contactor: Taiwan Shihlin

Line Speed Meter: Taiwan FOTEK

Bearing: NSK, SKF

3. Parameters

| Machine model | ZD-90+45 |

| Pay-off type | Double shaft type pay-off |

| Pay-off bobbin | PN400-800 |

| Screw diameter(mm) | Φ90 |

| Screw L/D ratio | 26:1 |

| Extrusion output (kg/hr) | 300 |

| Main motor power | 75kW |

| Wire diameter(mm) | Φ6-50 |

| Cooling Trough | Single layer/Double layers/U-type |

| Accumulated cable length(m) | 200 |

| Traction power | 11kW |

| Line speed(m/min) | Max. 300 |

| Take-up type | Shaft-mounted/Bundle |

| Coiling Method | Auto Coiling |

| Take-up bobbin | PN800-1250 |

| Take-up power | 7.5kW |

4. Technical support

Our engineer team has rich experience working overseas for customer

on-site service. This ensure us able to provide our customers

widely range of support, such as overseas on-site installation,

talent training, long-term technology updating services, etc.

Q1:What is your main brands for the electrical and mechanical

parts?

A:Oversea famous brand such as German siemens motor, Japanese nsk

bearing and yaskawa inverter etc.

Q2:What is your difference with other suppliers?

A:What we could offer to other customer is not only the machine

itself, also we could offer: factory design, production process

design , QC control, talent training, assist machine and raw

material offering .

Q3:What's the payment terms?

A:T/T,30% deposit and 70% balance before delivery, can be

negotiable also.